1.) SF-Type Wet Scrubbers/Membrane (Wet Solution)

Wet scrubbers push contaminated gas streams through a water solution to remove any inorganic contaminants. This type of scrubber is commonly used across all types of industries because of its efficiency. Any facility that produces corrosive gases or fumes can benefit from a wet scrubber.

Wet scrubbers work by taking contaminated gas through a water-based solution to get rid of any pollutants that remain in the water.

Compared to dry scrubbers, they are a more cost-effective solution in the long run. When functioning properly, wet scrubbers can remove over 99% of airborne particulates, which means that you can be confident in the quality of your facility’s gas streams before they enter the environment.

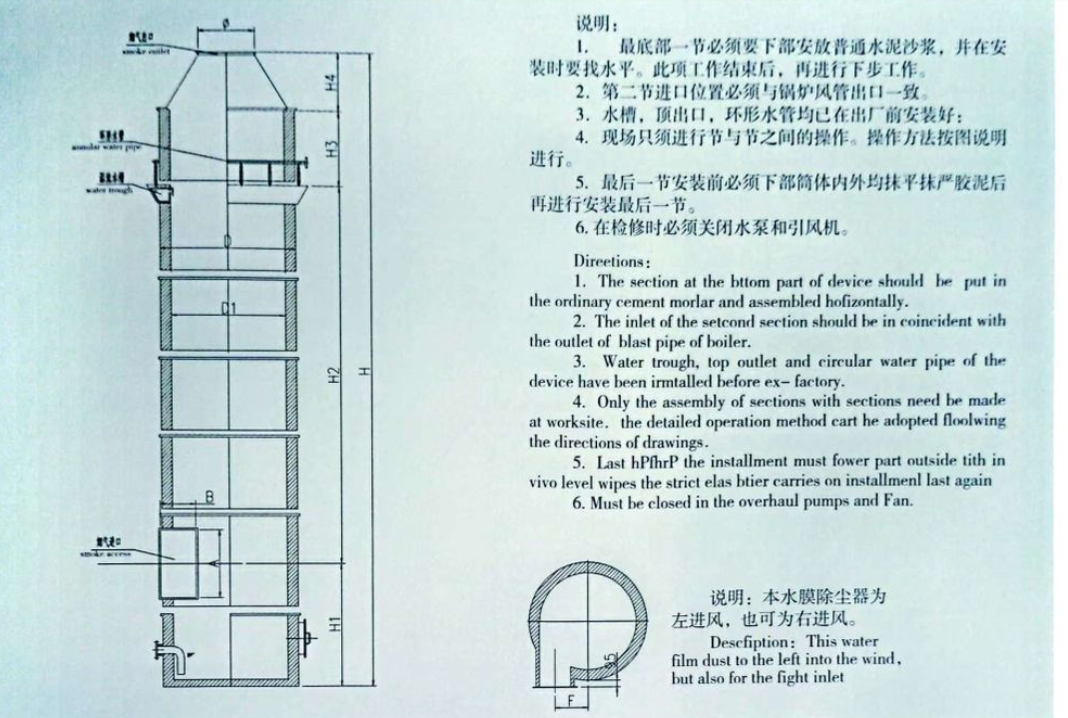

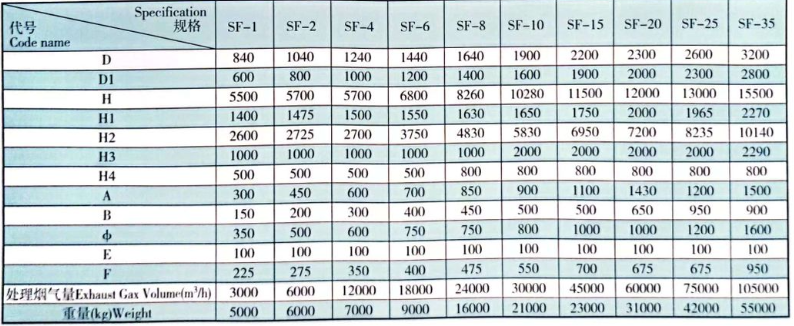

Below are the drawing of list specification and dimension:

Advantage Feature:

1.) The processing of flue gases can be handled safely

2.) High-temperature and high-humidity gas streams can be handled without condensation issues or temperature limits

3.) Collected particulate matter cannot escape once collected

4.) It’s possible to effectively neutralize some of the more corrosive gases

5.) Solid and gas particulate matter can be absorbed with one system

6.) You don’t need huge amounts of space for the installation of a wet scrubber

Pengunjung hari ini

Pengunjung hari ini Pengunjung Bulan ini

Pengunjung Bulan ini  Pengunjung Online

Pengunjung Online