1.) YLW Back to page

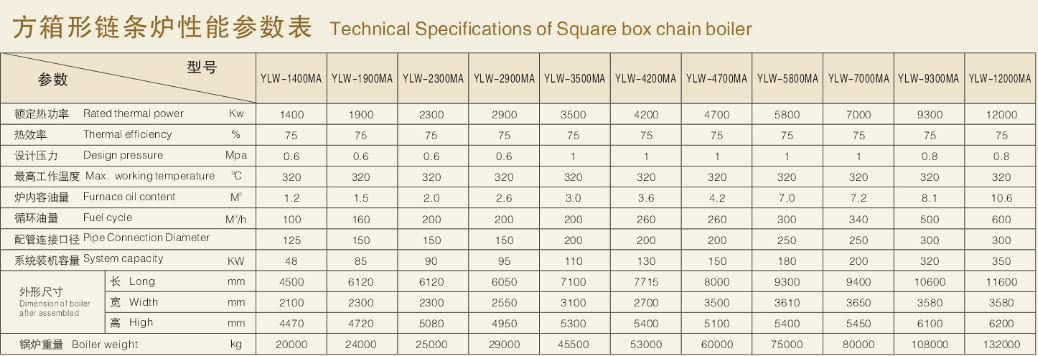

Transpiration : 1900-33000 KW

Design Pressure : 1.1 MPaG

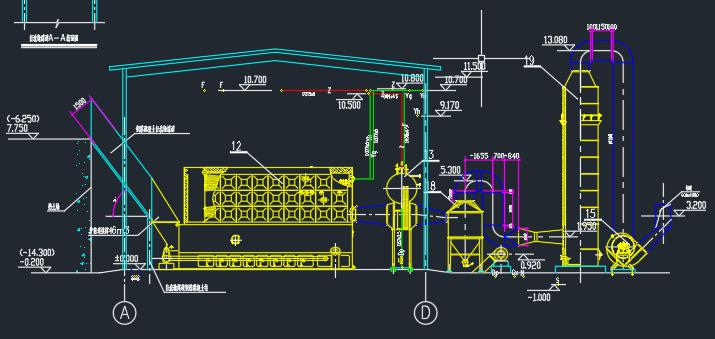

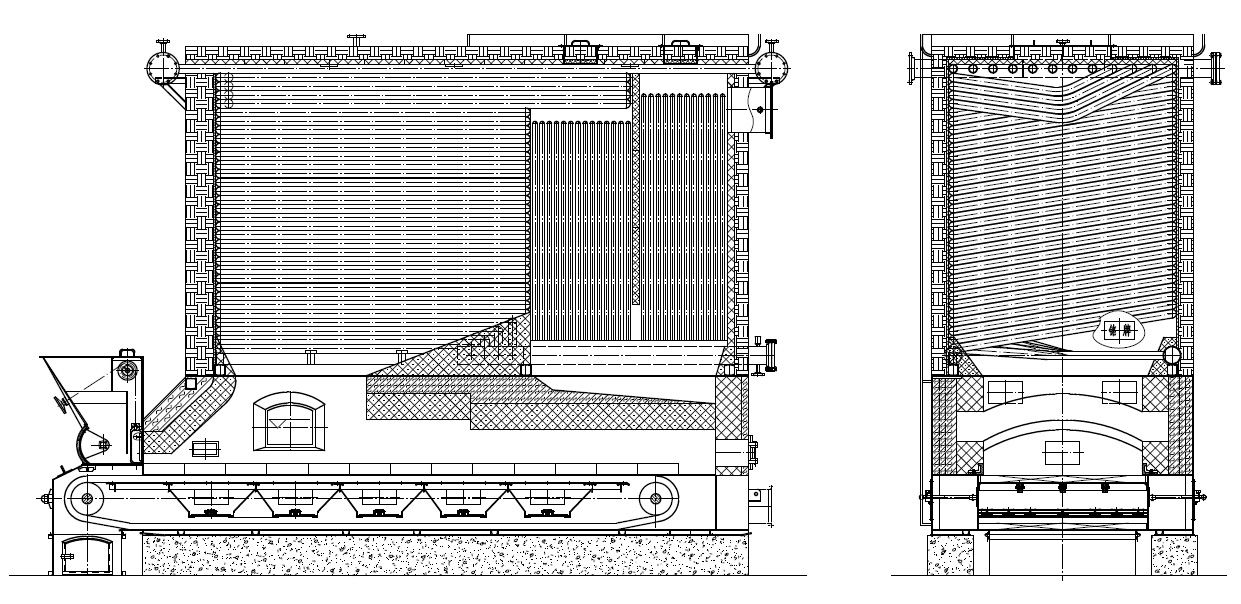

YLW organic heat-medium boiler is the packaged forced circulation chain grate boiler. Front section of boiler body is the hearth radiation heating area consisting of closely-aligned double-square coils. The rear section is the convection flush heating area of coil tube bank. Boiler is structured into the body drum on the combustion hot fume chamber. Heat from the boiler is used to heat the air as required for the boiler combustion in the air pre-heater. Then fume exhausts outside with chimney via the dust collector and draught fan.

- Simple installation and short installation period. Just combine the upper body and lower combustion chamber;

- Himple consists of double closely-aligned coils to ensure the sufficient heating area, reduce the surface heat load of pipe and handle the heat transfer oil safety;

- Reasonable medium flow. Heat transfer oil flows from the lower intlet to the upper outlet. Gas generated during the operation stays in the boiler hardly and can exhaust easily;

- Sound design of boiler vault. Fume can stay in the hearth long enough for better combustion;

- Heating area in the diversion fume chamber. Use the division to avoid direct flushing from hot fume and to effectively prevent the fume short circuit from the falling fume divisions.

(See type on the table below)

Pengunjung hari ini

Pengunjung hari ini Pengunjung Bulan ini

Pengunjung Bulan ini  Pengunjung Online

Pengunjung Online