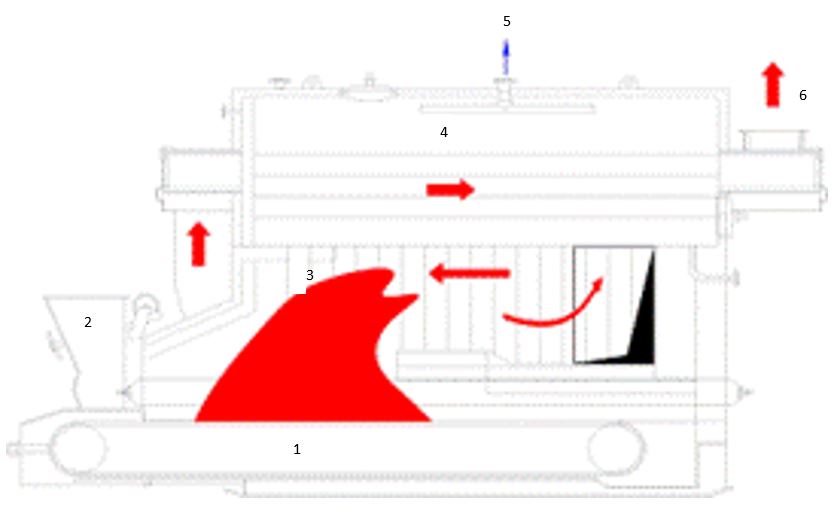

1.) DZL series traveling grate stroke packaged boiler Back to page

Capacity : 1-20 t/h

Design Pressure : 0.7-2.45 MPaG

Steam temperatur : Saturated

Combustion type : Chain Grate

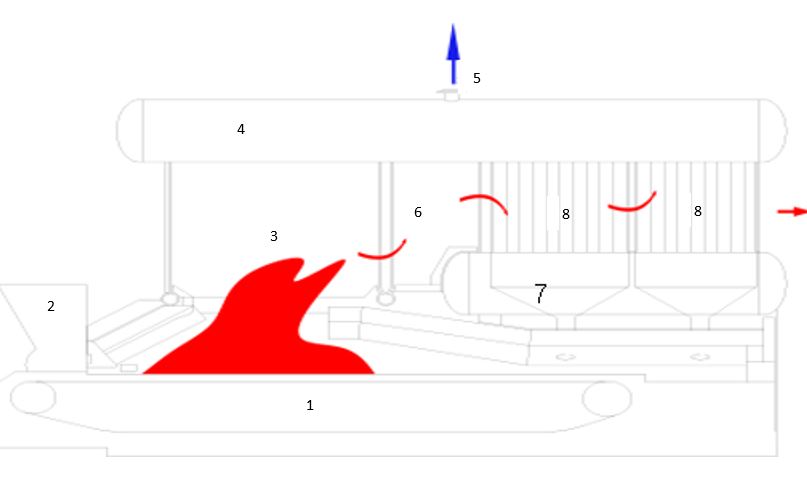

| 1. Traveling Grate Stoker | 4. Steam Drum |

| 2. Coal Hopper | 5. Steam Outlet |

| 3. Furnace | 6. Gas Exit |

Features of DZL Series Boiler :

- Boiler proper adopts the arched tube plate, improving strength safety margin and simplifying the stay;

- The internal threaded fire tube has a good effect of heat transference and high heat effeciency;

- The mechanization combustion is environment friendly and energy saving;

- The auxiliaries are completely provided and the equipment is delivered as a whole.

2.) SZL series water tube boiler

Capacity : 4-25 t/h

Design Pressure : 1.25-3.8 MPaG

Steam temperatur : Saturated

Combustion type : Chain Grate & Traveling Grate

| 1. Traveling Grate Stoker | 5. Main Steam Valve |

| 2. Coal Hopper | 6. Final Combustion Zone |

| 3. Furnace | 7. Bottom Drum |

| 4. Upper Drum | 8. Convection Tube |

Features of SZL Series Boiler:

- The body adopt longitudinal double-drum structure, full layout of heating surface and high thermal efficiency;

- Mechanized combustion;

- Environment friendly and energy saving;

- Complete auxiliaries offered and high self-control;

- The body and the base are separately delivered;

3.) SHL series field-assembled coal fired boiler

Capacity : 35-110 t/h

Design Pressure : 2.45-5.4 MPaG

Steam temperatur : Superheated

Combustion type : Chain Grate Spreader with Reversal Grate

| 1. Chain Grate Stoker | 8. Bottom Drum |

| 2. Coal Hopper | 9. Economizer |

| 3. Furnace | 10. Air Preheater |

| 4. Final Combustion Zone | 11. Hot Air Outlet |

| 5. Steam Outlet | 12. Cold Air Inlet |

| 6. Upper Drum | 13. Flue Gas Exit |

| 7. Convection Tubes |

4.) Field Assembled Fluidized bed & Circulating Fluidized Bed Boiler (CFB)

Capacity : 10-150 t/h

Steam temperatur : Superheated

Press & Temperature According Customer

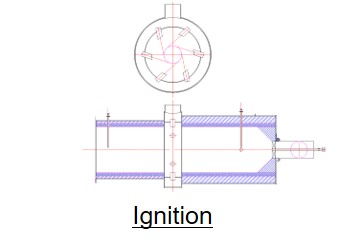

| 1. Igniter | 9. Low Temperature Superheater |

| 2. Coal Feeder | 10. Economizer |

| 3. Furnace | 11. Second Stage Air Preheater |

| 4. Fire Gas | 12. First Stage Air Preheater |

| 5. Steam Drum | 13. Cold Air Inlet |

| 6. Steam Outlet | 14. Hot Air Outlet |

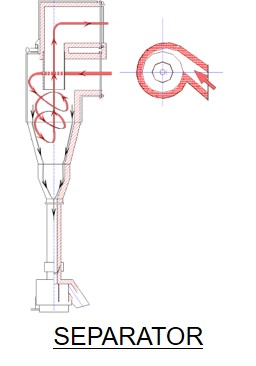

| 7. Tight Temperature Superheater | 15. Cyclone Separator |

| 8. Attemperator (reduce steam temperature) |

Fluidized Bed Boiler Main Technical Features:

High temperature cyclone separator: HT erosion resistant material, flexible connection, simple and reliable separator, HT fly ash circulated for re-combustion in the boiler;

Two areas of combustion: 60-70% of combustion air enters from under the bed and into the area of high density solids burning, 30-40% of the combustion air enters above this area, increasing the movement of burning solids into a more open area to ensure complete combustion;

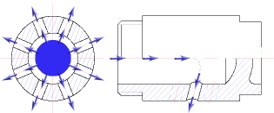

Wind Entering Device

Unique air feed devices: Design and spacing of air distribution heads ensure proper fluidizing of the bed;

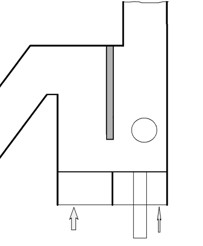

Material Reclamation Device

- Material reclamation device ensures unburned materials return to the bed for to complete combustion prevents slagging during the material circulation;

- Easy ignition: includes the manual and automatic ignition below the bed and also the ignition above the bed;

- Excess air coefficient alpha = 1.1 - 1.2;

- Automatic combustion control system reduces the gas discharge loss and avoids the slag forming, ensures the safety and high thermal efficiency.

Pengunjung hari ini

Pengunjung hari ini Pengunjung Bulan ini

Pengunjung Bulan ini  Pengunjung Online

Pengunjung Online